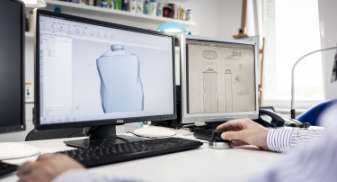

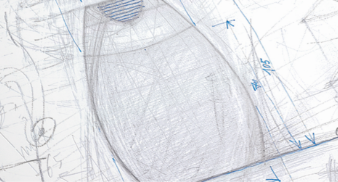

Tailored modelling is a perfect way to create unique concepts. We design and manufacture packaging for cosmetic, pharmaceutical, chemical, and food products from scratch, which involves a wide range of activities – developing models, making tools, manufacturing packaging, as well as providing visual design and comprehensive decoration services. We select the best manufacturing technologies, materials, and forms to transform innovative ideas into good products. Dedicated project managers help customers turn their ideas into reality, guiding them through each and every step of the process, and giving advice on best styles, materials, and decoration options.

Thanks to cutting-edge tools and systems, which allow us to control every stage of the project, we provide our customers with top-quality products and solutions that are tailored to their needs.

ORIGINAL EFFECTS

As a packaging manufacturer, we will create an original design which brings out the character of your brand, while individually selected and designed cosmetic packaging will make your company stand out thanks to not only the remarkable quality of your products, but also the appealing and practical look and application of bottles and caps.